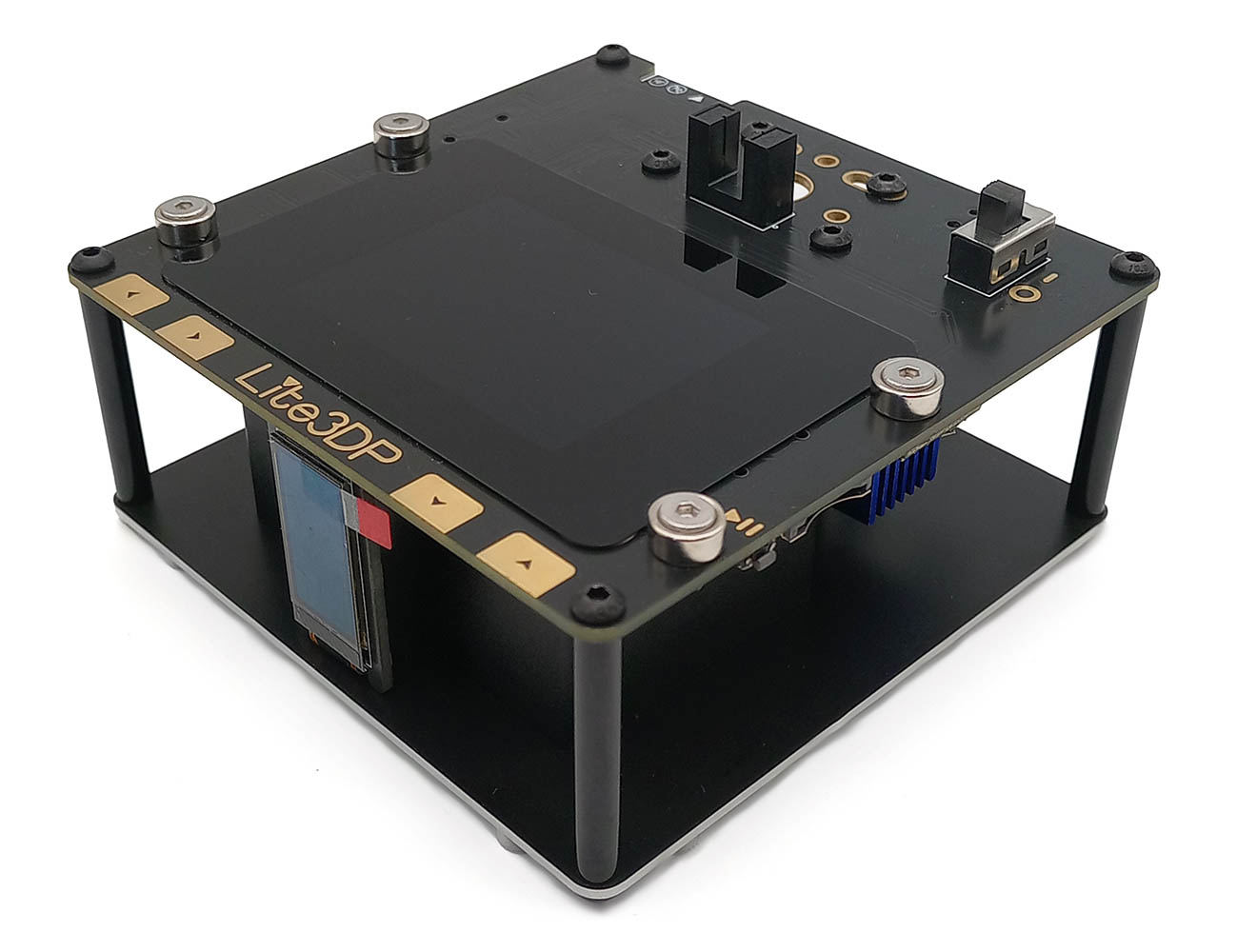

Lite3DP Gen 2

3D printing in your hands

After the successful crowdfunding campaign of the S1 model on Crowd Supply Lite3DP is introducing its second generation of experimental 3D printers with MSLA resin technology.

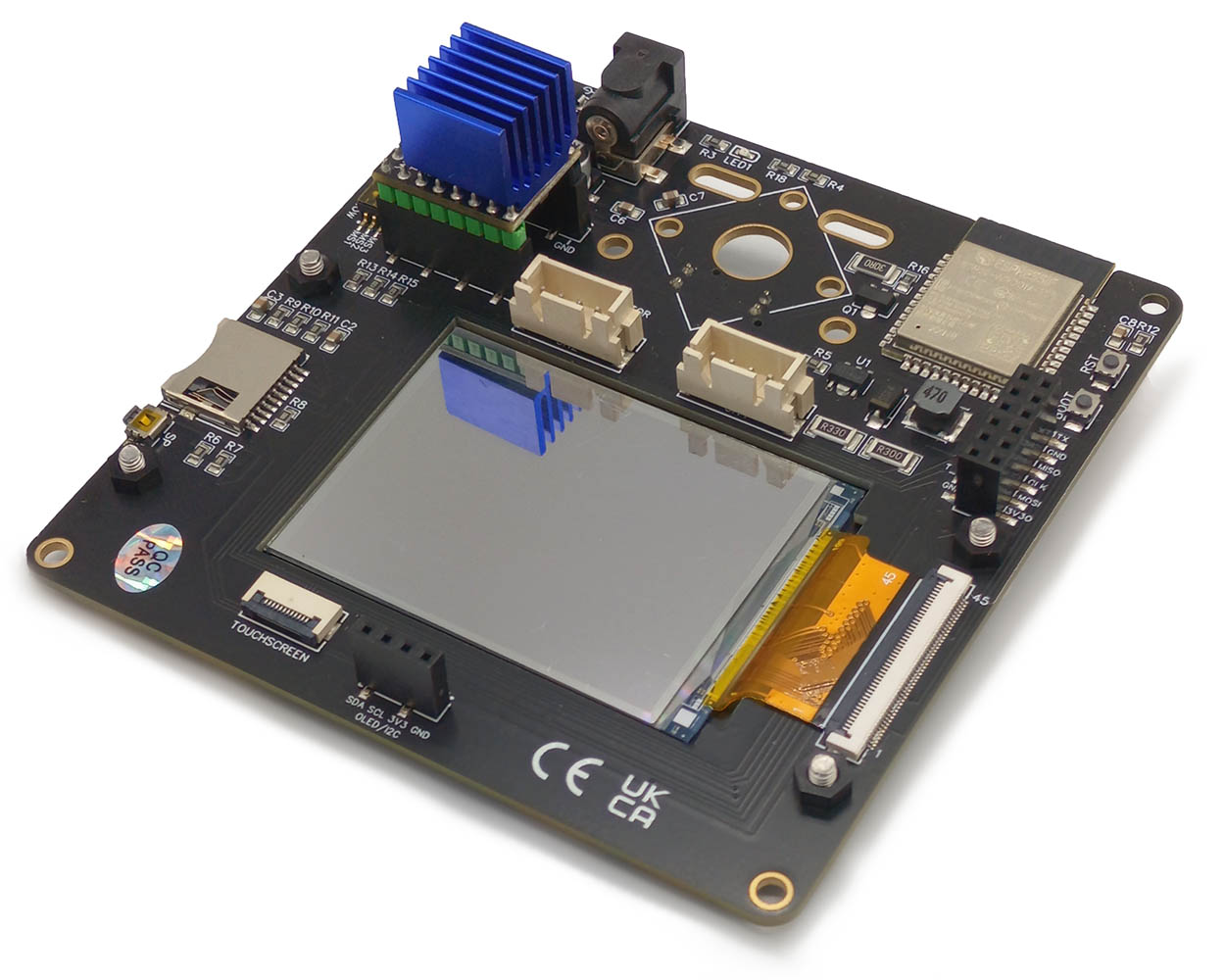

The new main electronic board was completely redesigned, enhancing all its features: surface mount components were used, eliminating all soldering on the upper face, the Arduino Pro Mini microcontroller was replaced by a powerful ESP32 (Arduino Open Source code) and a larger and higher resolution LCD display was included.

Main board

In the new design the base is an aluminum PCB, on which a state-of-the-art UV LED (405nm) and two white backlight LEDs are soldered. This achieves optimal heat dissipation and an intense UV light source for 3D printing.

In addition to the linear guide and POM nut, the improved mechanical system of the Gen 2 model includes a stable and precise Nema 8 motor with built-in leadscrew, a top bearing and a silent Trinamic TMC2209 driver (in “stepstick” format, for easy replacement or upgrade).

The combination of the new mechanics with the passive heat dissipation system makes the Lite3DP Gen 2 a completely silent machine.

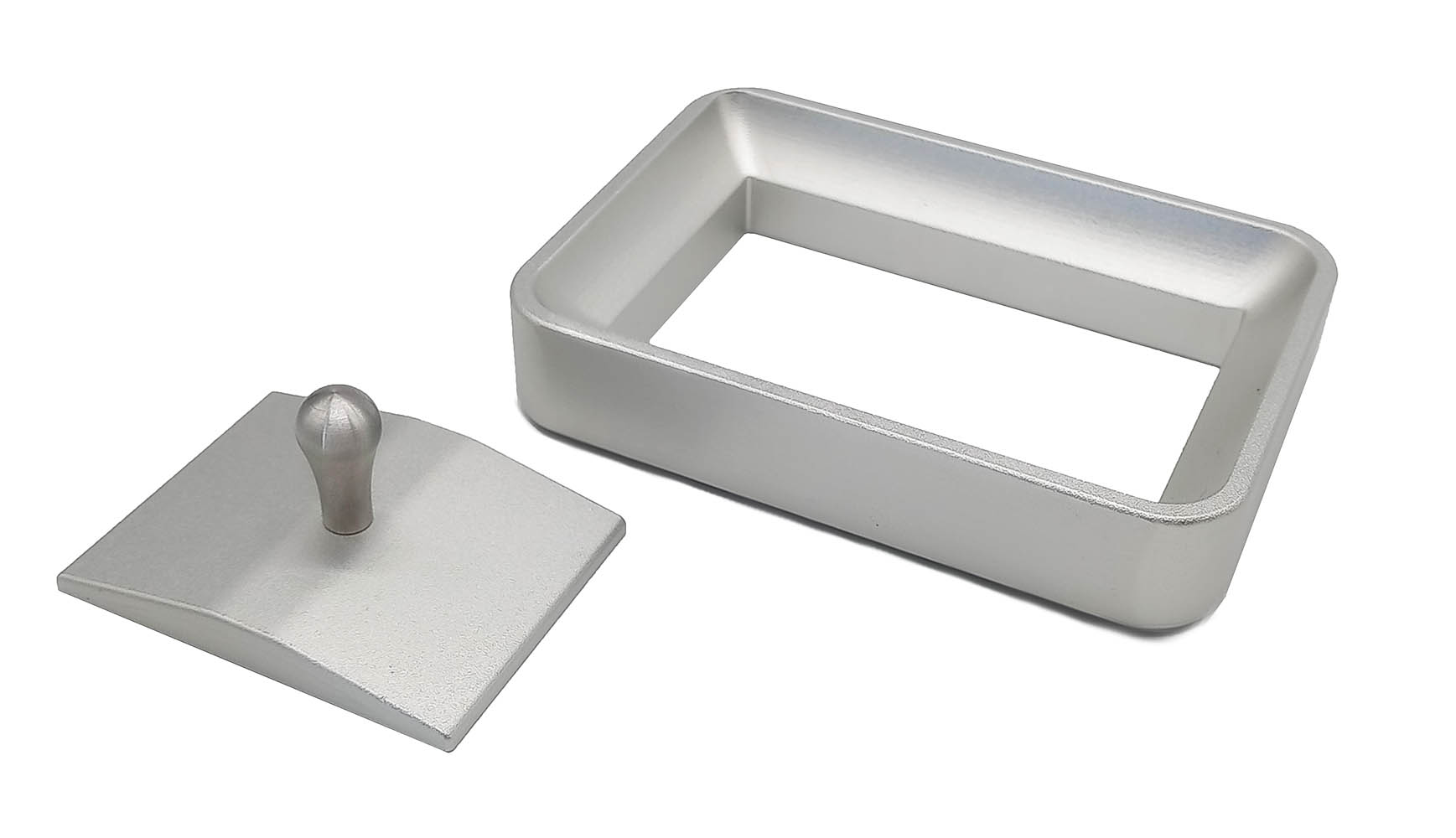

In order to collaborate in scientific experimentation and applications with high-cost resins, we have developed a system of miniature VAT and build platform, easily interchangeable with the standard ones. This set allows printing using a very small volume of resin (2 mL), reducing the build volume to 20 x 20 x 80 mm. Both the VAT and the platform are made of polished 316L stainless steel (Ra ≤ 0.8), sterilizable. In addition, a magnetic nylon support is included, which allows the use of the mini VAT in the same way as a standard size one without making any modifications to the machine (just replacing the hand knob screw with a regular M3x10 screw).

Please contact us if you have special requirements or need a custom development for scientific or industrial purposes.

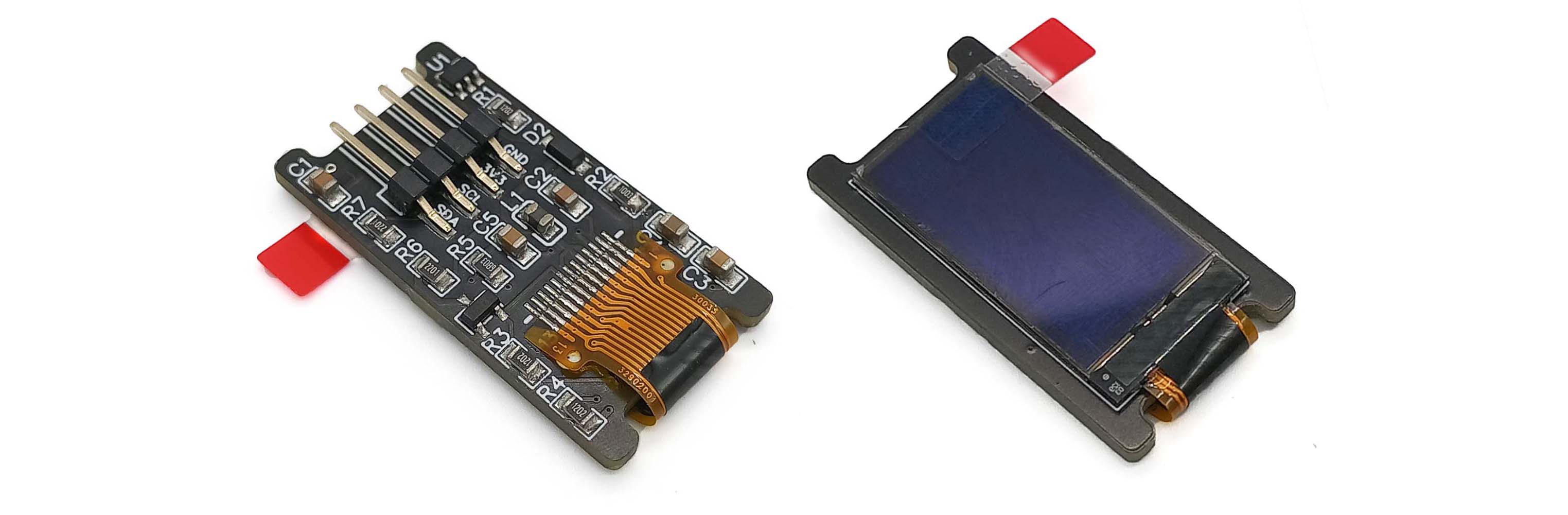

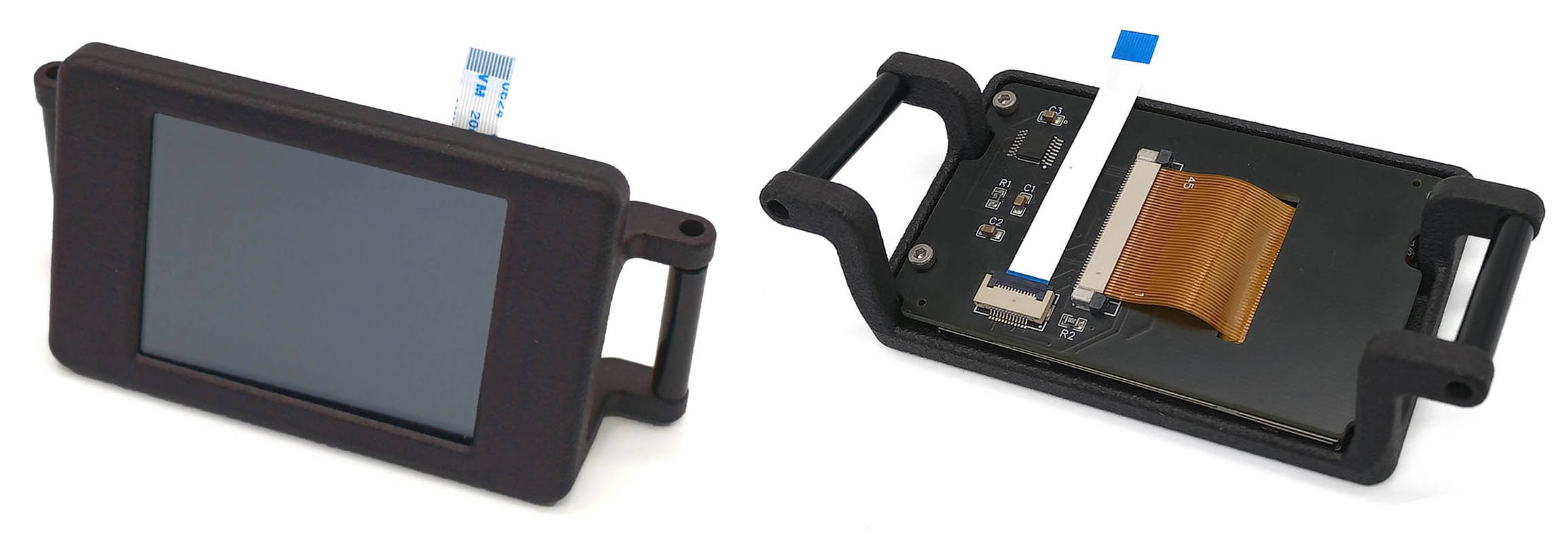

In order to enrich the user interface, two auxiliary displays are offered: an OLED display that shows the progress of 3D printing (while the main display works as a mask during 3D printing and also to navigate the selection menu), and a touchscreen display that also allows navigation through the selection menu.

The OLED display is incorporated in a minimal board, connecting electrically and mechanically through 4 pins with I2C interface. This same 4-pin output is also compatible with other OLED modules on the market.

OLED display

One of the most advanced novelties is the touchscreen auxiliary display, made up of the same high-resolution LCD display as the main board, as well as a resistive touch panel. It offers sharp images and a comfortable and fluid selection interface. It is attached to the Lite3DP through a simple casing and connected to the main board with an FPC cable.

Touchscreen display

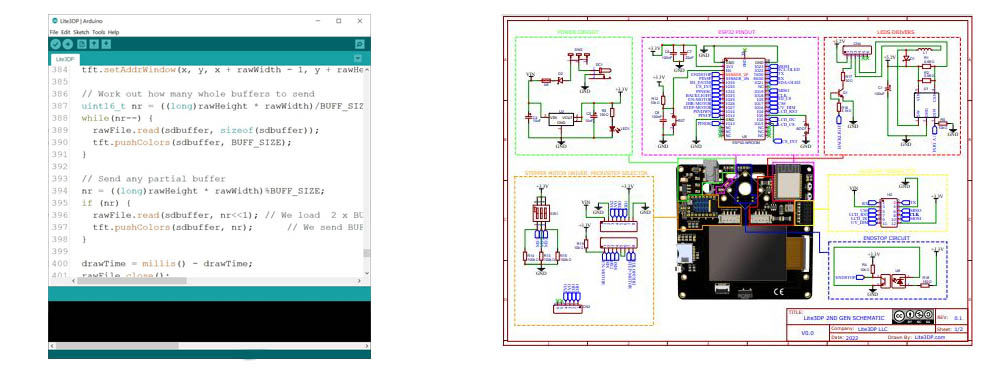

The new ESP32 microcontroller, in addition to allowing the use of a higher resolution display and richer programming, is capable of running a PNG format image decoder. PNG images are the standard output of the software that generates the sections of the parts to be 3D printed (know as "Slicer"). These images are read from a folder located on the micro SD card and displayed on the main LCD screen layer by layer, with UV light passing through and solidifying the liquid resin.

Therefore, it is only necessary to copy the folder of PNG images generated by the software to the micro SD card. Printing parameters are selected in the menu, allowing the same folder of images to be 3D printed with different resins and resolutions.

Lite3DP focuses on creating Open Source designs. Schematic diagrams, electronic board manufacturing files, Arduino code, bills of materials, 3D parts, and drawings are available for each of the models on the Lite3DP Github.

Having detailed documentation allows a deep understanding of the technology and makes it easier to modify, update and repair.

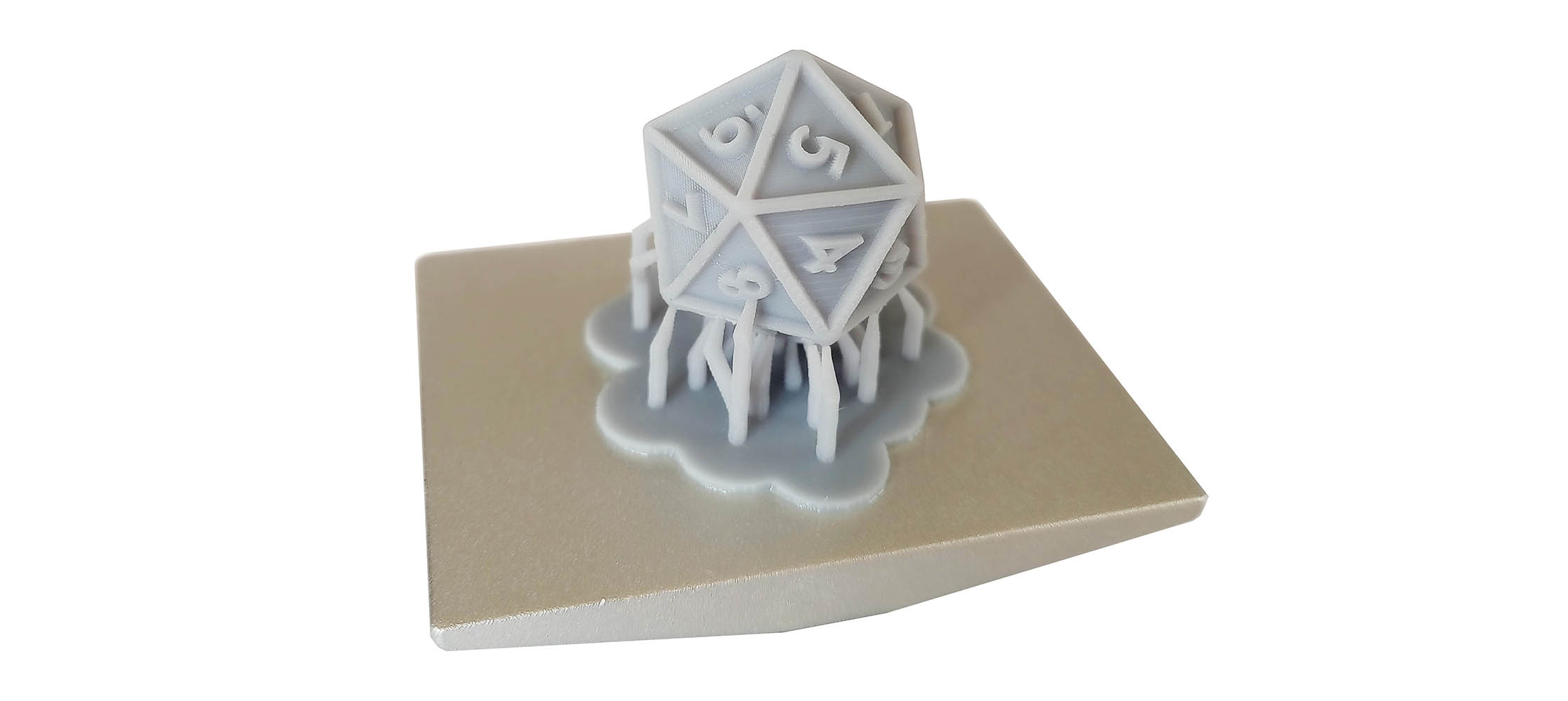

Lite3DP has achieved a highly accurate 3D printer, with an improved interface and simplified workflow.

It is ideal for manufacturing all kinds of small parts with extraordinary details and surface finish. If you would like to enter the world of high-resolution 3D printing, you value a silent, small, low-consume machine and Open Source, you are familiar with Arduino (or want to learn), Lite3DP can become a great tool for you.

| Global size | 100 x 100 x 167 mm |

| Technology | MSLA resin 3D printing |

| Build volume (W x L x H) | 36,7 x 48,8 x 80 mm (+34% than S1) |

| XY resolution | 0.115 mm (222ppi, +22% than S1) |

| Z resolution | 0.025, 0.05 and 0.1 mm |

| Compatible resins | All UV-405 nm (standard, industrial, flexible, castable, dental, etc.) |

| Print speed | Up to 40 mm/h |

| Data input | Micro SD card autonomous operation |

| Slicer software | Chitubox, Lychee, Prusa Slicer, Voxeldance Tango and more. No need for additional image conversion software. Windows, Linux and Mac compatible |

| Micocontroller | Espressif ESP32 |

| Firmware | Arduino code, open source |

| Stepper motor - mechanics | Nema 8, built-in leadscrew. Ultra-silent TMC 2209 driver. POM nut, top bearing, linear guide |

| Tray/VAT | Aluminum, magnetic attachment. 50cm3 capacity (1.7 fl oz.) |

| Weight | Less than 0.5 kg (17 oz.) |

| Power consumption | Less than 10W. 12V 1A, 5.5*2.1mm power supply |